Hey everyone, let’s dive into the fascinating world of electric motors, specifically those powering our electric transport revolution! We’ll be looking at TWO main types: DC motors and AC motors.

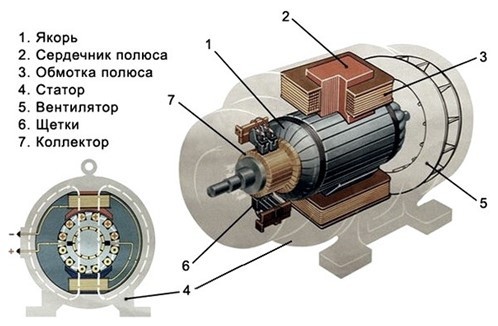

First up, DC motors. These are, in a nutshell, relatively simple devices. They work by using direct current electricity to create a magnetic field that interacts with another magnetic field, causing rotation. Think of it like this: you have a permanent magnet, and then a rotating electromagnet. The interaction between these TWO magnetic fields generates the torque, or rotational force, that turns the wheels of your electric vehicle, or spins the propeller of your drone. There are several types of DC motors used in electric transport, each with its own strengths and weaknesses. Brushed DC motors are the simplest and cheapest, but they tend to have shorter lifespans due to wear and tear on the brushes. Brushless DC motors, on the other hand, are more efficient, longer-lasting, and offer better performance, but they come with a slightly higher price tag. They’re becoming increasingly popular in electric vehicles because of their superior efficiency and reliability. You’ll find them in everything from e-bikes to electric cars, and even some electric aircraft. The key difference lies in how the magnetic field is switched – brushed motors use physical brushes to make and break the connection, while brushless motors use electronic switching, eliminating the need for those wear-prone brushes. This electronic switching also allows for much more precise control over the motor’s speed and torque.

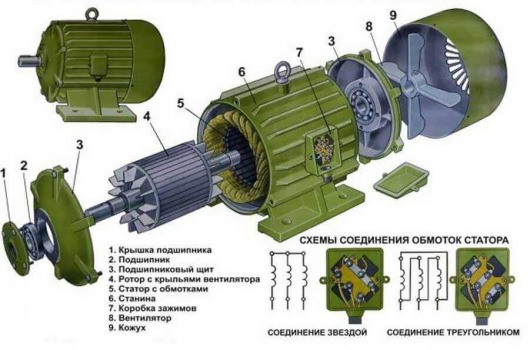

Now, let’s shift gears and talk about AC motors. These are a bit more complex than DC motors, but they offer some significant advantages, especially in higher-power applications. AC motors use alternating current electricity, which means the direction of the current flow reverses periodically. This allows for a more efficient and powerful motor design. The most common type of AC motor used in electric transport is the induction motor, also known as an asynchronous motor. These motors are incredibly robust, require minimal maintenance, and are highly efficient. They work on the principle of electromagnetic induction – a changing magnetic field induces a current in the rotor, creating a magnetic field that interacts with the stator’s magnetic field, resulting in rotation. Induction motors are particularly well-suited for applications requiring high torque at low speeds, making them ideal for electric vehicles that need strong acceleration from a standstill. Another type of AC motor gaining traction is the synchronous motor. These motors are known for their precise speed control and high efficiency, especially at higher speeds. They use permanent magnets or electromagnets in the rotor, which are synchronized with the rotating magnetic field in the stator, resulting in very smooth and controlled rotation. You’ll often find synchronous motors in applications where precise speed control is crucial, such as in some high-performance electric vehicles or electric powertrains requiring precise speed synchronization. The choice between an induction motor and a synchronous motor often comes down to the specific application requirements and the desired balance between cost, efficiency, and performance. Both are powerful contenders in the electric transport arena.

So, there you have it – a look at the TWO main types of electric motors driving the electric transport revolution. Each type has its own unique characteristics and advantages, making them suitable for a wide range of applications, from small e-bikes to large electric buses and everything in between. Understanding these differences is key to appreciating the technological advancements shaping our future of sustainable transportation.

Hey everyone, let’s dive into the fascinating world of electric motors powering our electric transport! We’ll be looking at TWO main types: asynchronous and synchronous motors.

First up, asynchronous motors. These are also known as induction motors, and they’re incredibly common in electric vehicles, especially in more budget-friendly models. Why? Because they’re relatively simple, robust, and cost-effective to manufacture. They work on the principle of electromagnetic induction. Essentially, you have a stationary part called the stator, which contains electromagnets. When you supply electricity to the stator, it creates a rotating magnetic field. Now, the rotor, the spinning part of the motor, doesn’t have any direct electrical connections. Instead, the rotating magnetic field induces currents in the rotor, creating its own magnetic field. These TWO magnetic fields interact, causing the rotor to spin. It’s a pretty clever system!

One of the key advantages of asynchronous motors is their simplicity. They have fewer components than synchronous motors, making them less prone to failure and easier to maintain. This translates to lower maintenance costs over the lifespan of the vehicle. They also tend to be more tolerant of variations in voltage and frequency, which can be beneficial in situations where the power supply might not be perfectly stable. However, they’re not without their drawbacks. Asynchronous motors typically have slightly lower efficiency compared to synchronous motors, meaning they might consume a little more energy to produce the same amount of power. They also generally have a slightly lower power density, meaning they might be larger and heavier for the same power output. Think of it like this: they’re workhorses, reliable and efficient enough for many applications, but maybe not the absolute peak of performance.

Now, let’s shift gears and talk about synchronous motors. These are a bit more sophisticated than their asynchronous counterparts. In a synchronous motor, the rotor’s speed is directly synchronized with the frequency of the alternating current supplied to the stator. This is achieved through various methods, often involving permanent magnets or field windings on the rotor. The precise synchronization allows for incredibly precise control over the motor’s speed and torque. This makes them ideal for applications requiring high precision and responsiveness, such as high-performance electric vehicles.

The benefits of synchronous motors are significant. They boast higher efficiency than asynchronous motors, meaning they can travel further on a single charge. They also offer higher power density, allowing for smaller and lighter motor designs for the same power output. This is particularly important in electric vehicles where weight is a crucial factor in range and performance. Furthermore, synchronous motors can operate at higher speeds and deliver higher torque at lower speeds, making them well-suited for demanding driving conditions. However, the increased complexity comes with a higher manufacturing cost and potentially higher maintenance costs down the line. They are also more sensitive to variations in voltage and frequency, requiring more sophisticated control systems. Think of these as the performance-tuned engines of the electric motor world – powerful, efficient, but requiring more precise engineering and potentially more specialized maintenance.

So, there you have it – a comparison of asynchronous and synchronous motors in the context of electric transport. Both play vital roles, each with its own strengths and weaknesses, catering to different needs and price points within the electric vehicle market. The choice between them often depends on the specific requirements of the vehicle, balancing performance, efficiency, cost, and overall design considerations.