So, we’re tackling a common problem for Nissan Leaf owners in colder climates: battery heating. Specifically, we’re building TWO different variants of a high-voltage battery heater for our Nissan Leaf X-Cross AZE0, and I’m going to walk you through both. This is a project that requires a decent amount of electrical knowledge and comfort working with high voltages, so please, if you’re not comfortable with this, don’t attempt this at home. Safety first, always.

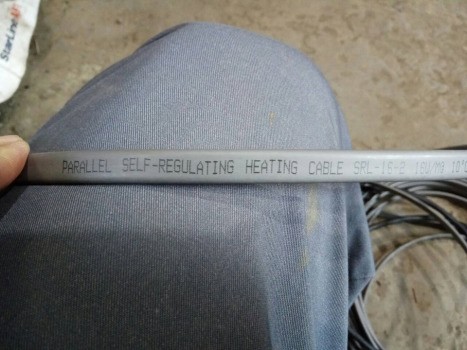

Let’s start with the first variant. This one focuses on simplicity and ease of construction. We’re using readily available components, nothing too specialized. The core of this heater is a set of heating elements, carefully chosen for their wattage and compatibility with the Leaf’s high-voltage system. We’re talking about THREE HUNDRED watts here, a level that provides effective heating without overloading the system. The key is proper insulation; we’re wrapping the heating elements in high-temperature resistant material to ensure efficient heat transfer to the battery pack and prevent any short circuits. The wiring is crucial; we’re using thick gauge wire capable of handling the current, and all connections are meticulously soldered and insulated with heat-shrink tubing. This isn’t a project where you can skimp on quality materials. We’re also incorporating a simple on/off switch, easily accessible for manual control. This first variant is all about reliability and straightforward functionality. It’s a solid, dependable solution, perfect for those who prioritize simplicity.

Now, let’s move on to the second variant. This one is a bit more advanced, incorporating smartphone control for a more convenient and sophisticated experience. We’re using a microcontroller, specifically an ESP THREE TWO, to manage the heating elements. This allows for precise temperature control and remote operation via a custom app on your smartphone. The microcontroller monitors the battery temperature using a temperature sensor placed strategically near the battery pack. The app provides real-time temperature readings and allows you to adjust the heating level remotely. This adds a layer of convenience and control that the first variant lacks. The wiring is more complex, of course, requiring careful consideration of the microcontroller’s power requirements and communication protocols. We’re using a robust power supply to ensure stable operation of the microcontroller and the heating elements. This variant requires a bit more technical expertise, but the added convenience and control are well worth the extra effort. Imagine pre-heating your battery remotely before you even leave the house on a freezing winter morning! It’s a game-changer.

Remember, both variants involve working with high voltages. Always exercise extreme caution and prioritize safety. If you’re unsure about any aspect of this project, it’s best to consult with a qualified electrician before proceeding. This isn’t a project for beginners, but with careful planning and execution, you can significantly improve your Nissan Leaf’s winter performance. And don’t forget to subscribe for more DIY projects and electric vehicle modifications!

So, we’ve covered the first design for a Nissan Leaf high-voltage battery heater, and now let’s dive into the second variation. This one takes a slightly different approach, focusing on efficiency and ease of installation. Instead of using a complex network of heating elements like the first design, this version utilizes a single, high-wattage heating element strategically placed within the battery pack’s thermal management system. This means we’re not trying to heat the entire battery, but rather, we’re targeting the key areas that experience the most significant temperature drop during cold weather. This targeted approach leads to faster heating times and potentially lower energy consumption.

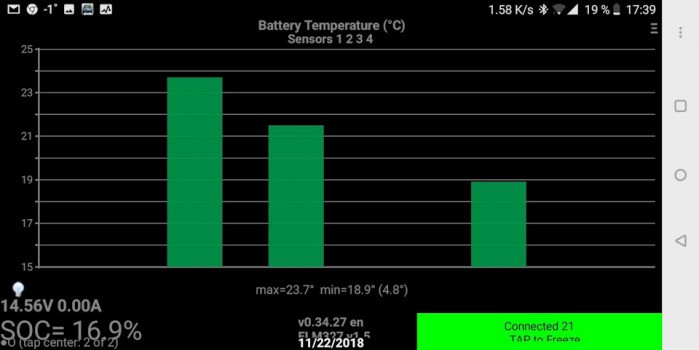

The key to this design is precision. We need to carefully select a heating element with the correct wattage and thermal characteristics to avoid overheating any components. We’re talking about a high-voltage system, so safety is paramount. I’ll show you exactly how I calculated the required wattage based on the battery’s thermal properties and the desired temperature increase. We’ll also discuss the importance of using appropriate thermal insulation to maximize efficiency and prevent heat loss. This insulation will be strategically placed around the heating element and within the battery pack itself, ensuring that the heat is directed where it’s needed most.

One of the biggest challenges with this design was integrating the heating element seamlessly into the existing thermal management system. It required careful modification and precise placement to avoid interfering with the battery’s cooling system. I’ll walk you through the process step-by-step, showing you the tools and techniques I used to ensure a clean and safe installation. We’ll also discuss the importance of using high-temperature resistant materials and connectors to withstand the heat generated by the heating element. Remember, we’re dealing with high voltages here, so any mistakes could be dangerous. Safety is always the top priority.

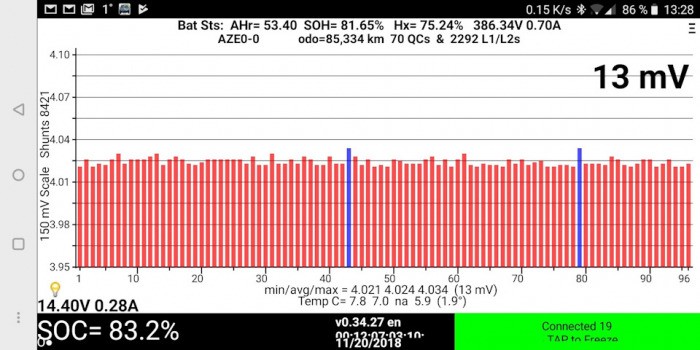

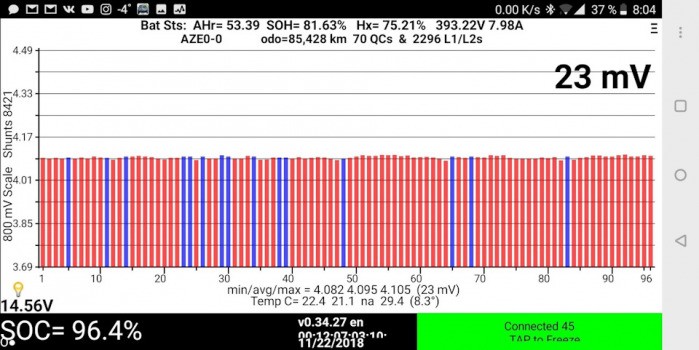

Now, let’s talk about the control system. This second variation uses a sophisticated temperature controller that monitors the battery’s temperature and adjusts the heating element’s output accordingly. This ensures that the battery is heated to the optimal temperature without overheating. I’ll show you the wiring diagram and explain how the controller interacts with the battery management system (BMS) to prevent any conflicts or damage. We’ll also discuss the importance of using a reliable power source for the heating element, ensuring that it receives a consistent and stable supply of power.

Finally, we’ll compare the performance of both heater designs. We’ll look at the heating times, energy consumption, and overall effectiveness of each design under various cold weather conditions. This comparison will help you decide which design is best suited for your needs and your level of comfort with electrical work. Remember, safety is always the most important factor when working with high-voltage systems. If you’re not comfortable working with electricity, it’s best to leave this project to a qualified professional. But if you’re confident in your abilities and follow all safety precautions, you can significantly improve your Nissan Leaf’s performance in cold weather. And don’t forget to check out the related news section below for more information on battery heating and winter driving tips.