Hey everyone, let’s dive into the world of electric motor maintenance. Keeping your electric motors running smoothly is crucial, and regular monitoring is key. So, what should you be looking for? Well, there are several vital indicators you need to keep a close eye on. First, pay close attention to the motor’s temperature. Excessive heat is a major red flag, often indicating problems like bearing wear, winding faults, or overloading. You should regularly check the motor’s temperature using a contact thermometer or infrared thermometer, comparing the readings to the manufacturer’s specifications. Another critical indicator is vibration. Excessive vibration can point to a variety of issues, including bearing damage, imbalance in the rotor, or problems with the motor’s mounting. Use a vibration meter to measure the level of vibration and compare it to acceptable levels. Next, listen carefully to the motor’s sounds. Unusual noises, such as grinding, squealing, or humming, can signal problems with the bearings, gears, or other internal components. Regularly inspect the motor for any signs of leaks, especially oil or grease leaks, which can indicate seal failure. Finally, monitor the motor’s current draw. A significant increase in current draw, compared to the motor’s nameplate rating, can indicate overloading, winding problems, or other issues. Regularly check the current using a clamp meter. Keeping an eye on these FIVE key indicators – temperature, vibration, sound, leaks, and current draw – will help you catch potential problems early and prevent costly repairs or downtime.

Now, let’s talk about how often you should service your electric motors. There’s no one-size-fits-all answer, as the frequency of servicing depends on several factors, including the motor’s size, type, operating conditions, and application. However, a good rule of thumb is to perform a visual inspection at least ONCE a month. This inspection should include checking for loose connections, damaged wiring, excessive wear, and any signs of overheating. More thorough servicing, including lubrication, bearing inspection, and cleaning, should be performed at least ONCE a year, or more frequently if the motor operates in harsh environments or under heavy loads. For motors operating in particularly demanding conditions, such as high temperatures, dusty environments, or corrosive atmospheres, more frequent servicing might be necessary, perhaps every THREE or SIX MONTHS. Remember, preventative maintenance is far cheaper than dealing with a major breakdown.

Finally, let’s discuss factors that can significantly complicate the use and maintenance of electric motors. Operating electric motors in harsh environments presents a significant challenge. Exposure to extreme temperatures, high humidity, dust, corrosive chemicals, or vibrations can drastically reduce the lifespan of a motor and increase the frequency of required maintenance. For example, high temperatures can lead to premature bearing failure and insulation degradation, while dust and dirt can clog ventilation systems and lead to overheating. Similarly, corrosive environments can damage motor components, leading to premature failure. Another complicating factor is overloading. Running a motor beyond its rated capacity puts excessive stress on its components, leading to overheating, bearing failure, and reduced lifespan. Regularly monitoring the motor’s load and ensuring it doesn’t exceed its rated capacity is crucial. Finally, improper installation and alignment can also significantly impact the motor’s performance and lifespan. Incorrect alignment can lead to excessive vibration, premature bearing wear, and reduced efficiency. Therefore, proper installation and regular alignment checks are essential for ensuring the long-term reliability of your electric motors. By understanding and addressing these factors, you can significantly extend the life of your electric motors and minimize downtime.

Okay, let’s dive right into maintaining your electric motors. Proper maintenance is key to extending their lifespan and preventing costly downtime. We’ll cover several crucial aspects, starting with what to look for when you first start the motor.

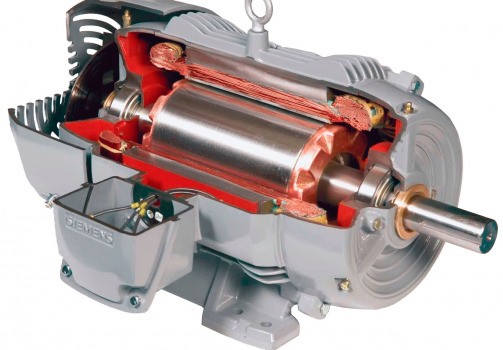

When you start your electric motor, pay close attention to the initial sounds. Is it running smoothly, or are there any unusual noises? A grinding sound could indicate bearing wear, while a high-pitched whine might suggest a problem with the windings. Also, feel the motor housing. Is it excessively hot? Overheating is a serious issue that can lead to motor failure. Check the temperature with a reliable thermometer; anything above ONE HUNDRED AND TWENTY degrees Fahrenheit is a cause for concern. Observe the motor’s vibrations. Excessive vibrations can indicate problems with the bearings, mounting, or even an imbalance in the rotor. A slightly noticeable vibration is normal, but anything significant warrants investigation. Finally, check the motor’s amperage draw. Compare it to the nameplate rating. A significantly higher amperage draw could indicate a problem with the motor windings, bearings, or even a mechanical load issue. Don’t hesitate to consult the motor’s manual for specific amperage guidelines. These initial observations are crucial for early detection of potential problems.

Now, let’s talk about troubleshooting. Troubleshooting an electric motor can seem daunting, but a systematic approach can help you pinpoint the problem. First, always disconnect the power supply before attempting any repairs. Safety is paramount! Once the power is off, visually inspect the motor for any obvious damage, such as loose connections, damaged wiring, or physical damage to the housing. Check the terminal connections for tightness and corrosion. Loose or corroded connections can lead to overheating and motor failure. Next, examine the bearings. If you suspect bearing problems, you might hear unusual noises during operation, or feel excessive vibration. Worn bearings need to be replaced. Remember, this requires specialized tools and knowledge, so if you’re not comfortable doing it yourself, call a qualified technician. If you suspect a problem with the windings, you’ll likely need a multimeter to test the insulation resistance. Low insulation resistance indicates a problem that requires professional attention. Remember, working with electrical components can be dangerous, so if you’re unsure about any aspect of the troubleshooting process, it’s always best to consult a qualified electrician.

Finally, let’s touch on some related news and updates in the world of electric motor maintenance. The industry is constantly evolving, with new technologies and techniques emerging to improve efficiency and reliability. Keep an eye out for advancements in predictive maintenance, using sensors and data analytics to anticipate potential problems before they occur. This proactive approach can significantly reduce downtime and maintenance costs. Also, stay informed about new regulations and safety standards related to electric motor maintenance. Staying up-to-date on these developments will help you ensure your motors are operating safely and efficiently. Regularly checking industry publications and attending relevant workshops can help you stay ahead of the curve. Remember, proactive maintenance is far more cost-effective than reactive repairs.